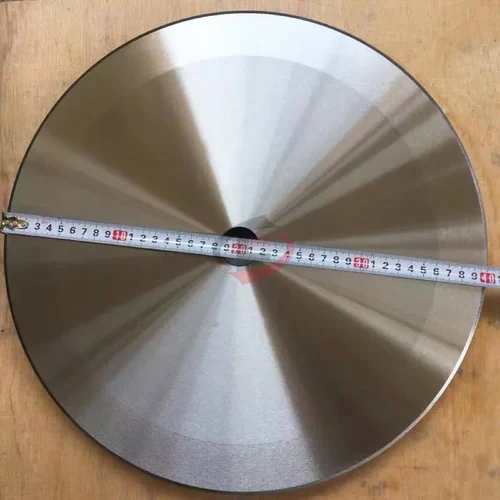

Cloth Cutting Blade

Product Details:

- Surface Treatment Teflon

- Shape Circular

- Design As your Request

- Type Cloth Cutting Blade

- Usage Industrial

- Blade Material Stainless Steel

- Handle Material Stainless Steel

- Click to view more

Cloth Cutting Blade Price And Quantity

- 1300 INR/Piece

- 50 Piece

Cloth Cutting Blade Product Specifications

- Teflon

- Cloth Industry

- Silver

- Teflon

- Circular

- Stainless Steel

- Cloth Cutting Blade

- Industrial

- Cloth Cutting Blade

- Stainless Steel

- As your Request

Cloth Cutting Blade Trade Information

- Cash Advance (CA), Cash in Advance (CID), Telegraphic Transfer (T/T)

- 1000 Piece Per Week

- 10 Days

- Yes

- Contact us for information regarding our sample policy

- Asia

- All India

Product Description

A cloth cutting blade is a specialized tool used for cutting cloth or fabric in industries such as textile manufacturing, garment production, upholstery, and other fabric-related applications. Here is a general description and specification of a cloth cutting blade:

-

Blade Design: Cloth cutting blades can come in various designs, including straight blades, circular blades, or rotary blades, depending on the specific cutting application and machine used. The blade length or diameter can vary based on the cutting requirements and fabric thickness.

-

Blade Material: These blades are typically made from high-quality steel or high-speed steel (HSS) to ensure durability and long-lasting sharpness. Some blades may also have a special coating or treatment to enhance cutting performance and resistance to wear.

-

Blade Edge: The cutting edge of a cloth cutting blade is sharp and precise to provide clean and accurate cuts. The blade may have a straight edge, serrated edge, or other specialized edge geometry, depending on the specific cutting application and fabric type.

-

Blade Mounting: Cloth cutting blades can be mounted on various cutting machines, such as fabric cutters, textile cutting tables, or automated cloth cutting systems. The blade is securely attached to the cutting machine to ensure stability and accuracy during the cutting process.

-

Cutting Mechanism: The cutting mechanism can vary depending on the type of cloth cutting blade and machine used. It can include straight blade cutting, rotary blade cutting, or oscillating blade cutting, among others. The cutting mechanism is chosen based on the specific fabric type and cutting requirements.

-

Application: Cloth cutting blades are specifically designed for cutting different types of cloth or fabric, including cotton, silk, polyester, linen, and more. They are commonly used in fabric manufacturing, garment production, upholstery, and other industries that require precise cloth cutting.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+